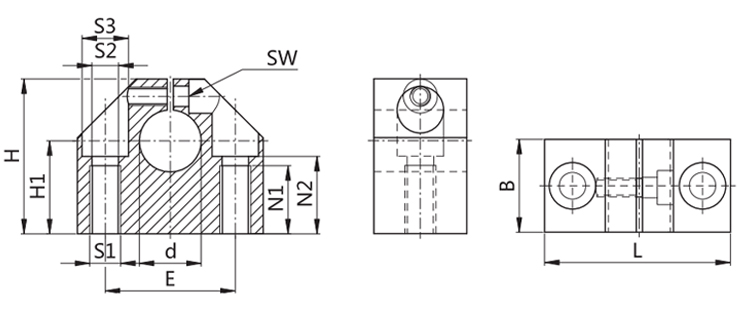

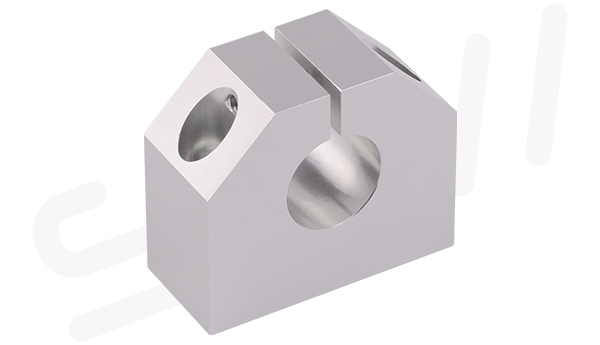

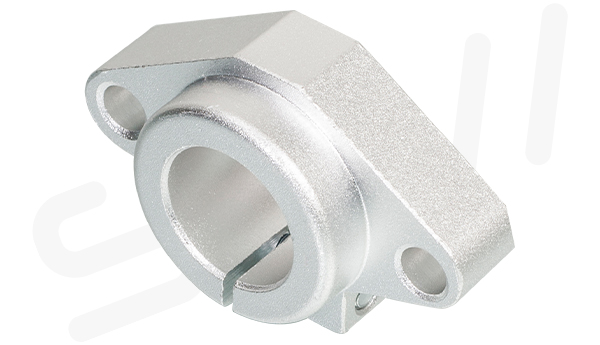

| product code | d | B | H | H1 ±0.02 |

L | S1 | S2 | S3 | E ±0.1 |

N1 | N2 | SW | weight [kg] |

| WA-08 | 8 | 18 | 28 | 15 | 32 | M4 | 3.3 | 6 | 22 | 9 | 13 | 2.5 | 0.04 |

| WA-12 | 12 | 20 | 35 | 20 | 43 | M6 | 5.2 | 10 | 30 | 13 | 16.5 | 3 | 0.1 |

| WA-16 | 16 | 24 | 42 | 25 | 53 | M8 | 6.8 | 11 | 38 | 18 | 21 | 4 | 0.15 |

| WA-20 | 20 | 30 | 50 | 30 | 60 | M10 | 8.6 | 15 | 42 | 22 | 25 | 5 | 0.23 |

| WA-25 | 25 | 38 | 60 | 35 | 78 | M12 | 10.3 | 18 | 56 | 26 | 30 | 6 | 0.41 |

| WA-30 | 30 | 40 | 70 | 40 | 87 | M12 | 10.3 | 18 | 64 | 26 | 34 | 6 | 0.53 |

| WA-40 | 40 | 48 | 90 | 50 | 108 | M16 | 14.25 | 20 | 82 | 34 | 44 | 8 | 0.99 |

| WA-50 | 50 | 58 | 105 | 60 | 132 | M20 | 17.5 | 26 | 100 | 43 | 49 | 10 | 1.25 |

| WA-60 | 60 | 74 | 130 | 75 | 164 | M27 | 22 | 33 | 124 | 43 | 59 | 10 | 2.95 |

No. 138, Linjiang Road, Jiashan County, Jiaxing City, Zhejiang Province